The TFRC is an internationally leading centre in fundamental and applied research in fluid flow, heat and mass transfer and fluid-structure interactions.

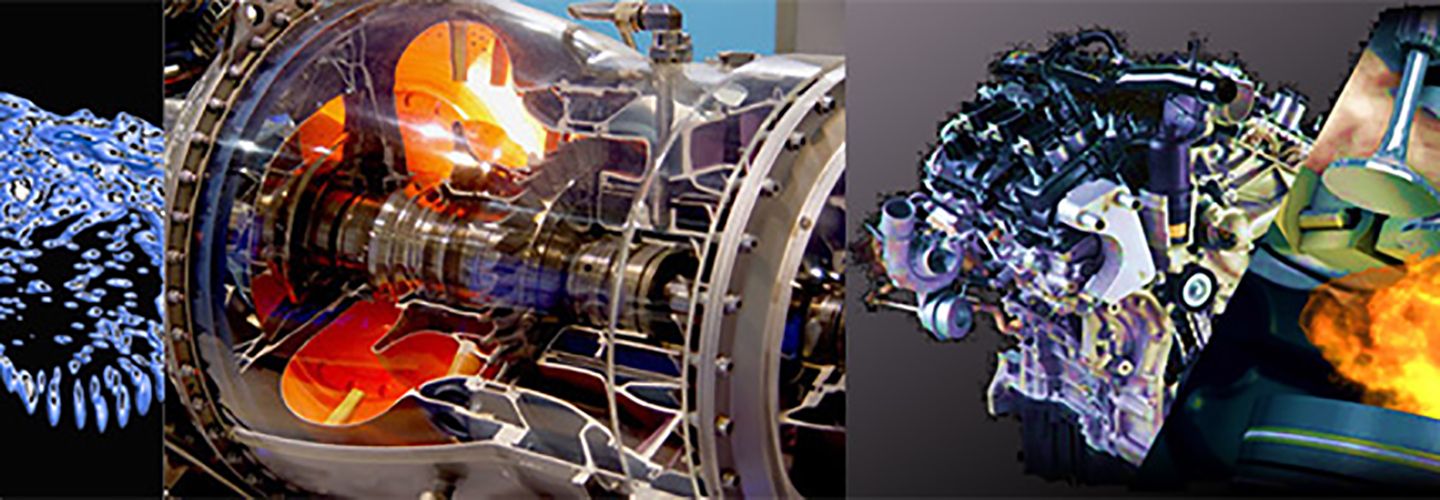

The TFRC is committed to interdisciplinary research methods needed for understanding the intrinsic physical phenomena in thermo- and fluid flow processes, as realised from molecular/nano- to macro-scales and their wide range of engineering applications addressing global challenges such as:

- Energy efficiency

- Emissions reduction

- Bio-engineering applications aiming towards improving well-being.

The centre computational and analytical tools and experimental facilities are devoted to conducting research in a range of applications from micro-scale devices to waste heat recovery, renewable energy systems, compressors, turbines, fuels and additives technology for a wide range of combustion engines, electrification technologies and various hydraulic/lubrication fluids and systems.

Application areas included:

- Power generation

- Transport

- Oil and gas

- Marine

- Food

- Health.

Advanced optical, laser and X-ray diagnostic techniques are assisting in the development of computational mechanics software for turbulent compressible and incompressible flows incorporating real-fluid thermodynamics.

Heat and mass transfer, phase-change, fluid-structure interactions and complex chemical processes are addressed.

Research is conducted in collaboration with global centres of excellence and relevant industry.

Thermo-Fluids Research Centre website

Visit the Centre's research microsite for more information about the Centre, including areas of research, projects and related activities.

People

- Dr Jafar Al Zaili

- Prof John Carlton

- Prof Manolis Gavaises

- Dr Ioannis Karathanassis

- Dr Foivos Koukouvinis

- Prof Ahmed Kovacevic

- Dr Matthew Read

- Prof Abdulnaser Sayma

- Dr Martin White

- Dr Qiang Ziang.